The precision range of Laptop mould: 0.02mm!

Laptop mould is an important factor affecting laptop prices. In simple terms, the mould is the injection mould, stamping mould, etc. used to produce the shell, from the aspect of the appearance design and the selected materials.

As for the selected materials of the mould, engineering plastics, magnesium-aluminum alloys (often referred to as magnesium alloys in shopping guides to appear noble) and carbon fiber materials are used. Generally speaking, the actual value of engineering plastics is relatively low, and it is also the most used material for some low-cost books; aluminum-magnesium alloy is higher than ABS engineering plastics, and the actual value is relatively high, and the weight is relatively light. It also helps the heat dissipation of notebooks. Therefore, it is the most popular material used in mainstream notebooks; carbon fiber material has the hardness of magnesium-aluminum and the relatively strong plasticity of engineering plastics. The price is higher than that of magnesium-aluminum alloy. It is generally used in relatively high-end products.

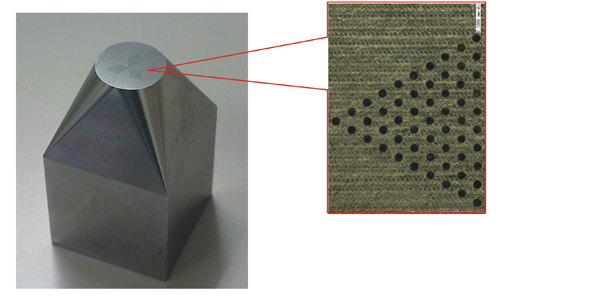

Open small hole

◆ Material: PX5 (HRC30)

◆ Workpiece size: 30X30X50mm

◆ Tool: φ0.08HSS micro drill

◆ Processing conditions: S=40,000min-1; F=50mm/min; cutting amount 0.005mm

◆ Processing depth: 0.16mm (L/D=2)

◆ Number of processing holes: 675 holes (Mitsubishi symbol)

◆ Processing time: 2 hours and 37 minutes

With one tool can complete the processing of 675 holes without burrs and deformation after processing.

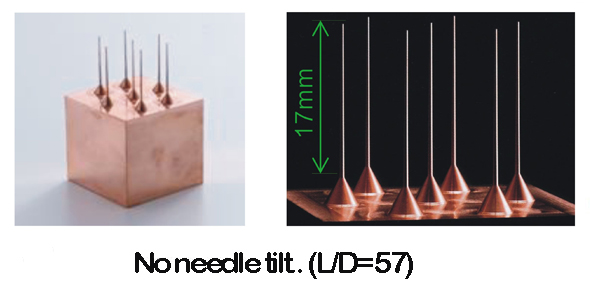

Copper Electrode Needle

◆ Material: Acid-free copper

◆ Workpiece size: 30X20X50MM

◆ Rough machining conditions: φ6 super hard milling cutter; S=8,000min-1; F=3,200mm/min; cutting amount 0.5mm

◆ Finishing conditions: D3R0.3 super hard ball cutter; S=6,400min-1

F=256min/min; cutting amount 0.02mm

◆ Toolpath: rough machining contour line; fine processing winding line

◆ Processing time: 21 minutes for rough machining; 5 hours and 22 minutes for fine machining

◆ Needle shape size: φ.3mmX0.5°; taper X length 17mm

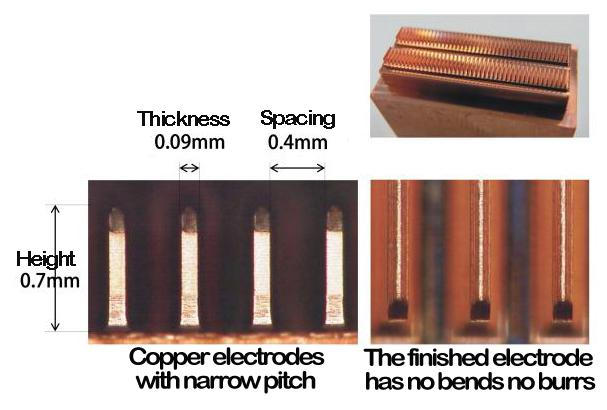

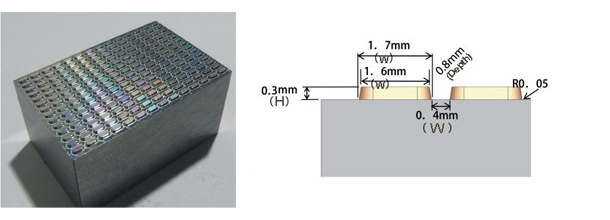

Copper electrode processing for narrow connectors

◆ Material: Copper pitch

◆ Workpiece size: 20X10X10mm

◆ Shape spacing: 0.4mm

◆ Using tool: super hard tool φ0.2 R0.05 ball knife

◆ Finishing conditions: S=40,000min-1; F=200mm/min; Allowance: 0.006mm; Cutting amount: 0.008mm

◆ Processing time: 8 hours and 20 minutes

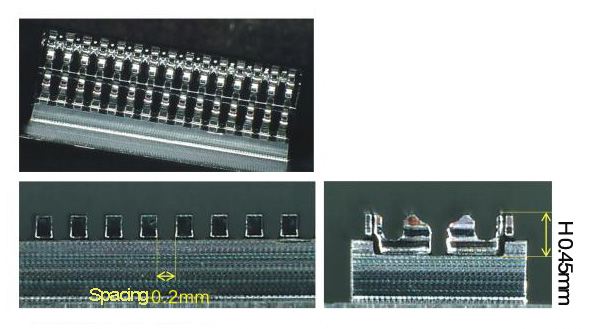

Processing of connector model

◆ Material: HAP10

◆ Workpiece size: 8X3X10 mm

◆ Pitch: 0.4mm

◆ Using tool: super hard tool R0.05 ball knife

◆ Finishing conditions: S=40,000min-1; F=40mm/min Machining allowance 0.002mm; Cutting amount 0.002mm

◆ Processing time: 16 hours and 20 minutes

The advanced connector mold processing greatly shortens the processing time compared with EDM (electrical discharge machining).

LED Mold

◆ Material: ELMAX (HRC60)

◆ Workpiece size: 30X20X15MM Number: 14X14=196

◆ Machining tool: R0.2CBN ball cutter D0.4 R0.05CBN milling cutter

◆ Processing conditions: S=40,000min-1, F=660mm/min; Cutting amount: 0.005mm; cutting spacing: 0.003mm

◆ Processing time: 7 hours and 9 minutes

Machining with super-hard tools effectively controls the wear of the tool, and even the multiple processing of small shapes can be processed with stable accuracy, shape and roughness.

Precision of the machined surface

◆ Spindle: Effectively avoid thermal deformation, high rigidity, low vibration

◆ Frame: High rigidity structure, low vibration of moving surface, damping capacity

◆ Feed shaft: High rigidity, low vibration